Understanding Final Drive Motors for Excavators

When it comes to the operation of excavators, a critical component that ensures optimal functionality is the final drive motor. These motors are essential for converting hydraulic power into rotational force, allowing the excavator to move effortlessly across various terrains. In this article, we will delve deep into what final drive motors are, their significance, and why choosing the right supplier, such as Shop Hydraulic America, is key to your machinery's success.

What Are Final Drive Motors?

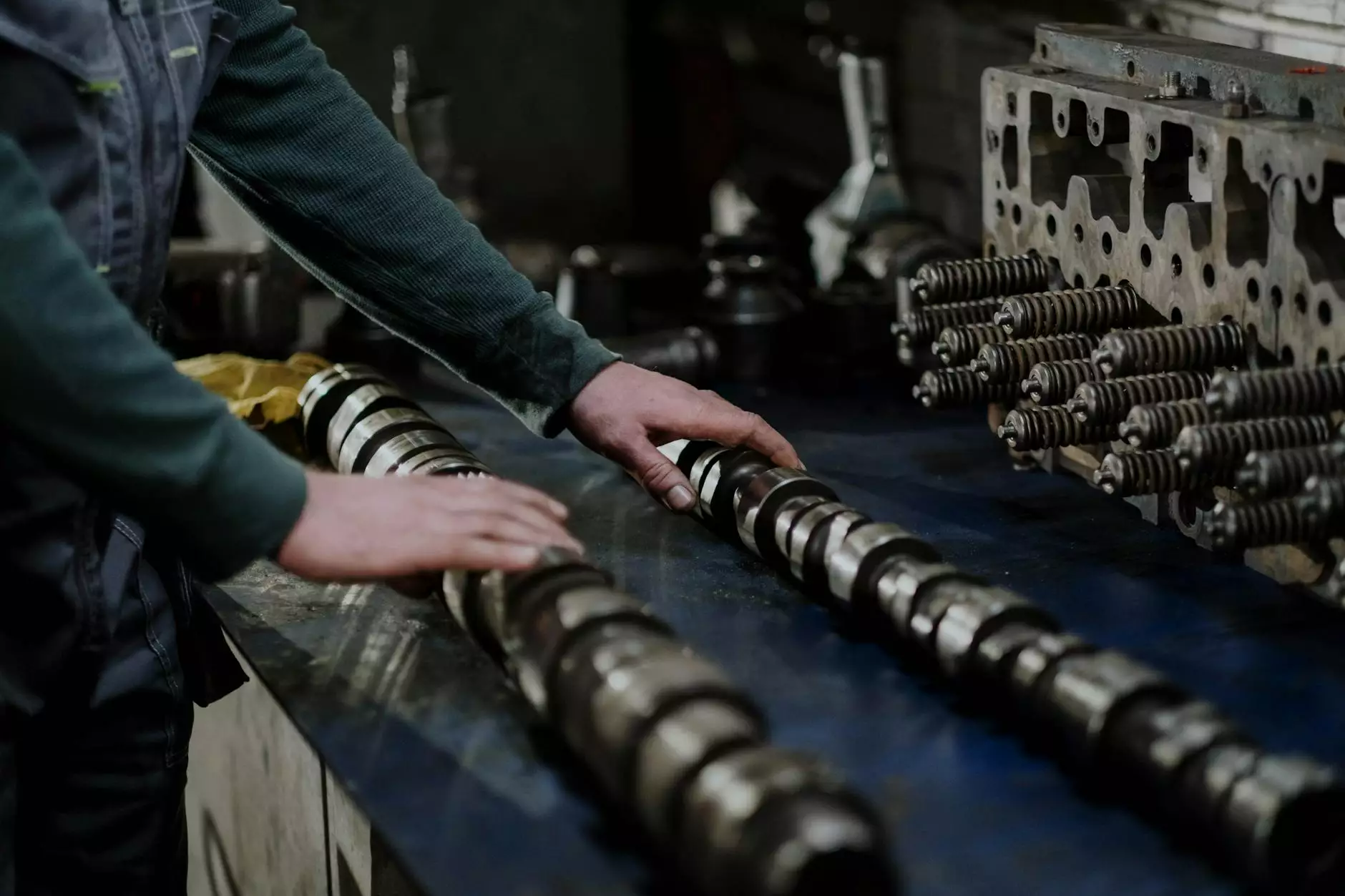

Final drive motors are powerful hydraulic motors that play a crucial role in the drivetrain of excavators. They consist of several components, including a hydraulic motor, a gearbox, and a housing that links the motor to the tracked or wheeled movement of the excavator. These motors are responsible for powering the travel system, rotating the apparatus, and ensuring the machine's various functionalities.

Components of Final Drive Motors

The operational efficiency of final drive motors stems from their intricate design. Here are the primary components:

- Hydraulic Motor: Converts hydraulic energy into mechanical energy.

- Gearbox: Reduces the speed of the motor while increasing torque.

- Housing: Encases the internal components and connects to the excavator's chassis.

- Output Shaft: Transfers power to the tracks or wheels.

The Role of Final Drive Motors in Excavator Performance

Final drive motors significantly influence the excavator's overall performance. They not only allow for swift movement across sites but also enhance the machine's ability to execute various tasks, such as:

- Digging: The motor's torque enables efficient digging capabilities.

- Lifting: Provides the necessary power for significant lifting operations.

- Rotating: Facilitates angular movement to navigate tight spaces.

- Traveling: Ensures smooth transitions between different job sites.

Benefits of High-Quality Final Drive Motors

Investing in high-quality final drive motors from a reputable supplier like Shop Hydraulic America offers numerous advantages:

- Increased Durability: Quality motors are built to withstand harsh conditions.

- Enhanced Efficiency: OEM parts ensure that excavators operate at peak efficiency.

- Improved Uptime: Reliable motors contribute to less downtime and maintenance costs.

- Optimal Performance: High-quality components offer better torque and speed control, enhancing machine performance.

Choosing the Right Supplier for Final Drive Motors

When selecting a supplier for your final drive motors, it is vital to consider several factors to ensure you're making the right choice. Here are some tips:

1. Industry Experience

Look for a supplier who has a solid track record in the excavator parts industry. An experienced supplier will be familiar with the intricacies of final drive motors and can provide valuable insights and recommendations.

2. Product Range

A reputable supplier will offer a broad selection of final drive motors to fit various excavator models. This includes OEM and aftermarket parts to ensure compatibility and performance.

3. Customer Support

Choose a supplier that provides exceptional customer service. This can include technical support, fast response times, and comprehensive warranties that give you peace of mind with your purchases.

4. Competitive Pricing

Pricing is also a crucial factor. A trustworthy supplier like Shop Hydraulic America offers competitively priced final drive motors without compromising on quality.

Shop Hydraulic America: Your Trusted Supplier

At Shop Hydraulic America, we pride ourselves on being a leading supplier of final drive motors for excavators. With a commitment to quality, customer satisfaction, and competitive pricing, our extensive inventory is designed to meet the needs of excavator operators and businesses alike. Here’s what sets us apart:

- Extensive Catalog: We stock a wide variety of final drive motors compatible with popular excavator brands.

- Quality Assurance: All our products undergo rigorous testing to ensure they meet industry standards.

- Expert Team: Our knowledgeable staff is ready to assist you in finding the right parts for your excavators.

- Fast Shipping: Quick turnaround times ensure your final drive motors reach you promptly.

How to Properly Maintain Final Drive Motors

Proper maintenance of your final drive motors can greatly extend their lifespan and performance. Here are some essential maintenance tips:

1. Regular Inspections

Frequent inspections help identify potential issues before they escalate. Look for leaks, abnormal sounds, or inconsistent performance.

2. Keep Hydraulics Clean

Ensure that your hydraulic system is free from contaminants. A clean hydraulic system promotes optimal performance and reduces wear on the final drive motor.

3. Monitor Oil Levels

Regularly check and maintain the appropriate oil levels. Use high-quality hydraulic oil as recommended by your manufacturer to ensure compatibility with your final drive motors.

4. Address Repairs Promptly

If any issues arise, such as strange noises or performance drops, address them immediately to prevent further damage.

Conclusion: Invest in Quality for Optimal Performance

Final drive motors are vital for the operational efficiency of excavators, making it imperative to choose high-quality components from a trusted supplier. Choosing Shop Hydraulic America ensures you are getting durable and efficient final drive motors that enhance the productivity of your machines. With the right motors and proper maintenance, your excavator can be a reliable asset in any construction project. For all your final drive motors for excavators needs, visit shophydraulicamerica.com and discover how we can support your business today!

final drive motors for excavators supplier